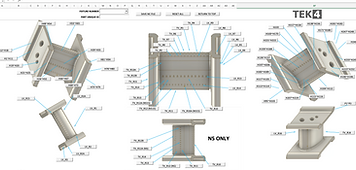

TEK4 Fast Hole Drill EDM Key Features

3 Steps to Accuracy

Accuracy and repeatability are critical elements when machining turbine components. TEK4s 3 Steps to Accuracy' procedure guarantees accuracy and repeatability in 3 simple steps. Set the machine, set the electrode and finally, set the part.

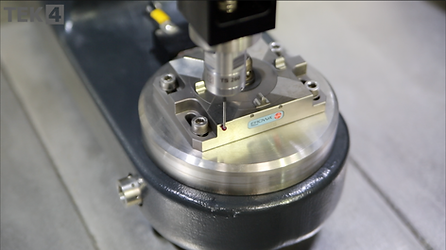

1 - Set the Machine

Using the CMM probe, integrated within the machine we set the machine, qualifying all 5 axes' and setting the work datums.

This process is completed in 3 minutes.

2 - Set the Part

Using the CMM probe, the part is measured at its reference points and is then "Nested" by the software using a 3-2-1 (Plane, Line, and Point) approach.

The machine is matching the CAD model that is embedded in the program with the physical part.

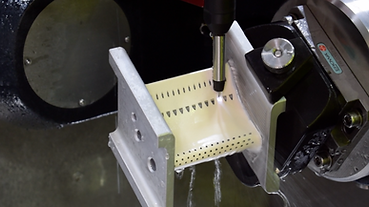

3 - Set the Electrode

This electrode setting procedure automatically sets new tool offsets values, removing the impact of any small variations that might be in the tool.

This second step eliminates the impact that these errors might have.

Laser Ablation (DAC)

TEK4’s optional DAC (Drill After Coating) technology uses a high-frequency fibre Laser to remove non-conductive coatings. This technology is confined within the FHD EDM machines to offer a solution to drill after coating.

The big advantage of having the EDM head and the Laser head in the same machine is a perfect geometrical correlation between the 2 processes. Reducing lead times by not having to transfer the parts between two machines and reduced inventory since there is no need to have parts at two different machines.

This technology process can be used on shaped diffusor holes as well as straight holes.

Key features

-

High-Frequency FibreLaser

-

High-Speed Accuracy Head

-

Automatic Calibration

-

100w Laser Power

-

Single Operation Dual Process

Step 1: Automatic calibration

Step 3: Precision fast hole drill EDM

Step 2: High frequency fibre Laser Ablation

Step 4: Single solution dual process

Repair Technology System

The machine is optionally supplied with a camera system that allows easy adaptive programming of Industrial Gas Turbine repaired components where new drilled holes need to be drilled relative to existing holes.

This system represents a breakthrough in flexibility, performance and ease of integration. This powerful vision system performs fast and accurately while its compact footprint easily fits into any TEK4 machine.

An integrated camera and lighting system is included to identify the location of the holes already drilled on the part – this is picked up by the EDM head.

Each time the camera system is picked up the position is calibrated by moving to a known feature on the datum bore.

Then the camera moves to identify the location of the reference holes that were selected by the operator, an automatic correction is applied to ensure that the new holes drilled are aligned to the existing holes.

Before automatic correction is applied

After automatic correction is applied

5 Essential Core Technologies EDM

Class-Leading EDM Performance

TEK4s PulseTech EDM technology is specifically designed for rapid EDM hole drilling in Aero and IGT parts. Flexible parameter process programming and adaptive software combine to give an outstanding performance.

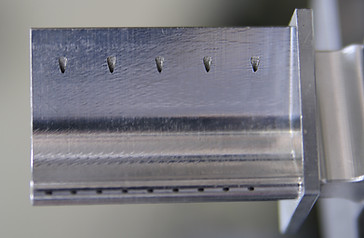

Pre-Breakthrough Detection

Pre-Breakthrough Detection automatically detects the onset of the beginning of electrode breakthrough. Once detected, EDM parameters are automatically engaged to improve and speed up the electrode breakthrough.

This is particularly valuable on acute angles and also compensates for casting thickness variations.

Automatic Breakthrough Detection

A programmable Breakthrough Detection system is used to prevent electrode overrun, especially when breaking into small cavities.

Breakthrough Detection compensates for casting variations and improves quality.

Advanced Shaped Cooling Hole Capability

TEK4s Shaped Cooling Hole Technology combines accuracy and flexibility with process speed. TEK4’s latest shaped hole drilling uses AFC (Adaptive Feedrate Control) which brings 30% improvement in shaped hole drilling times.

Data Collection

Each drilled hole application has a distinct process fingerprint. This is the sum of all the process variables. By graphing this process, improvements become immediately clear and by comparing current performance to previous performance process stability can be ensured.