Machine Features

6g Control System

TEK4s latest user interface has been completely updated and re-designed, enabling TEK4’s advanced features to be easily accessible and programmed.

The latest generation control system has advanced connectivity, allowing real-time data gathering and remote status monitoring.

The new control system has on-screen documentation, providing manuals, training videos and customer machine care videos.

Key Points

-

User-Friendly

-

On-Screen Manuals

-

On-Screen Training and Customer Machine Care Videos

-

Connectivity – Remote control; Remote Data Analysis; Remote Status Monitoring

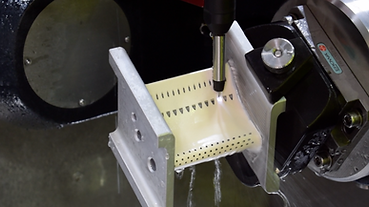

TEK4's Tooling

TEK4s new tooling system includes in-built through-flushing, high accuracy and repeatability guides, and holders. TEK4’s curved guides allow for non-line-of-sight drilling.

Unlike other manufacturers, TEK4’s tooling is extremely simple, making it both reliable and cost-effective.

Laser Ablation (DAC)

TEK4’s optional DAC (Drill After Coating) technology uses a high-frequency fibre Laser to remove non-conductive coatings. This technology is confined within the FHD EDM machines to offer a solution to drill after coating.

The big advantage of having the EDM head and the Laser head in the same machine is a perfect geometrical correlation between the 2 processes. Reducing lead times by not having to transfer the parts between two machines and reduced inventory since there is no need to have parts at two different machines.

This technology process can be used on shaped diffusor holes as well as straight holes.

Key features

-

High-Frequency FibreLaser

-

High-Speed Accuracy Head

-

Automatic Calibration

-

100w Laser Power

-

Single Operation Dual Process

Step 1: Automatic calibration

Step 3: Precision fast hole drill EDM

Step 2: High frequency fibre Laser Ablation

Step 4: Single solution dual process